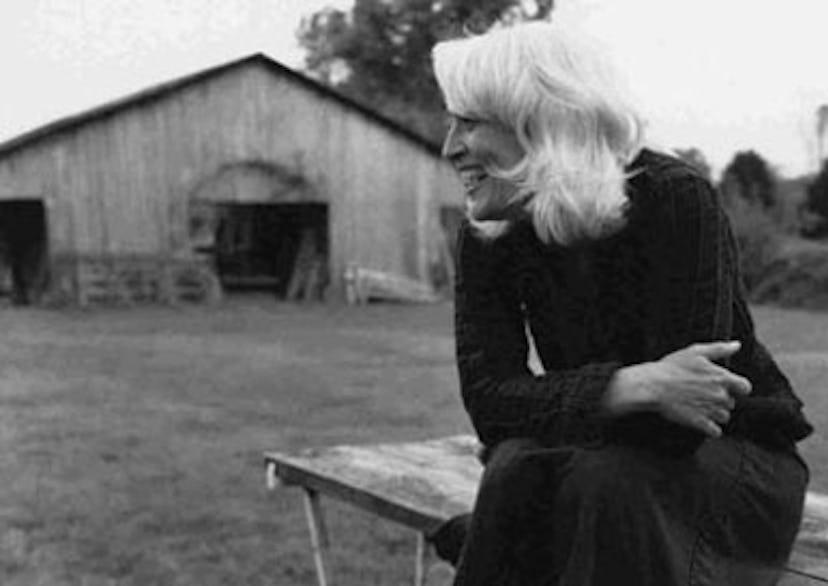

Five Minutes with Natalie Chanin

Natalie Chanin modernized homespun fashion with her first collection of one-of-a-kind t-shirts under her Project Alabama label back in 2000. Hiring local quilters and sewers from her hometown of Florence, Alabama, Chanin was preaching...

Natalie Chanin modernized homespun fashion with her first collection of one-of-a-kind t-shirts under her Project Alabama label back in 2000. Hiring local quilters and sewers from her hometown of Florence, Alabama, Chanin was preaching the importance of slow, local design way before sustainability came into fashion. On the eve of her tenth anniversary as a designer, W caught up with Chanin at her company headquarters in Alabama:

I had been styling for ten years in Vienna, Austria and was on the path to become a documentary filmmaker. I came back to the States at the tail end of a sabbatical and through a series of events I had this vision that I wanted to make 200 one-of-a-kind t-shirts. I visited manufacturers and asked them to do some really elaborate techniques to reconstruct these vintage t-shirts that I had brought with me. I wanted a quilting stitch that I had remembered from my childhood, and I knew that if I wanted to get them done the way I envisioned it, I’d have to go home to Florence, Alabama. I came home a decade ago on December 23rd and started this project—at the time called Project Alabama—by first making a 22-minute documentary about old-time quilting circles called Stitch. We made the 200 shirts as a part of the film along with a hand-made catalog and sent it out to the fashion industry.

How did the brand take flight from there? We took the collection to New York and did a preview at the Hotel Chelsea. The first person that came to the show was Julie Gilhart from Barneys New York. She consequently asked her buyers to come to buy the t-shirts. We had a very successful first season and they said they’d like to continue to support the collection, so we started a full-fledged production facility. Project Alabama has now ceased operations, but Alabama Chanin is the culmination of what that project symbolized.

What makes your process so unique? Our company is really unusual. The entire process is linked from start to finish. Every piece is cut by hand, painted by hand, embellished by hand and constructed by hand. We only work with a certified organic cotton jersey grown by farmers in Texas. The cotton fiber is sent to North Carolina for spinning into thread, then to South Carolina for knitting into the fabric before being sent back to North Carolina to be dyed and lastly sent here to the studio to cut, paint and preparing for our artisans here in Florence. Every garment is numbered and signed by the artisan who constructs it.

How has it evolved over the past decade? I wasn’t in New York thinking that I was going to go home and make a sustainable clothing company. This journey has turned from one simple project to a ten-year journey. Alabama Chanin has evolved into a community… a company of farmers, fabric makers, artisans and our customers who support what we do.